Select Projects

The Past

The Future

It takes 22 subcontractors 8 Months to build the

average home.

A disjointed process.

This siloed approach leaves room for error at every turn. While expertise and efficiency may be the driving claims, advanced technology offers new ways to meet, exceed and ultimately raise standards.

An Onx home is constructed as 1system.

A coordinated process 30 Days build time.

From start to finish, every aspect of an Onx homes is part of a holistic design process perfected by cutting-edge technology. The result is impeccable construction imbued with a deep reverence for the details that give a home its innate beauty.

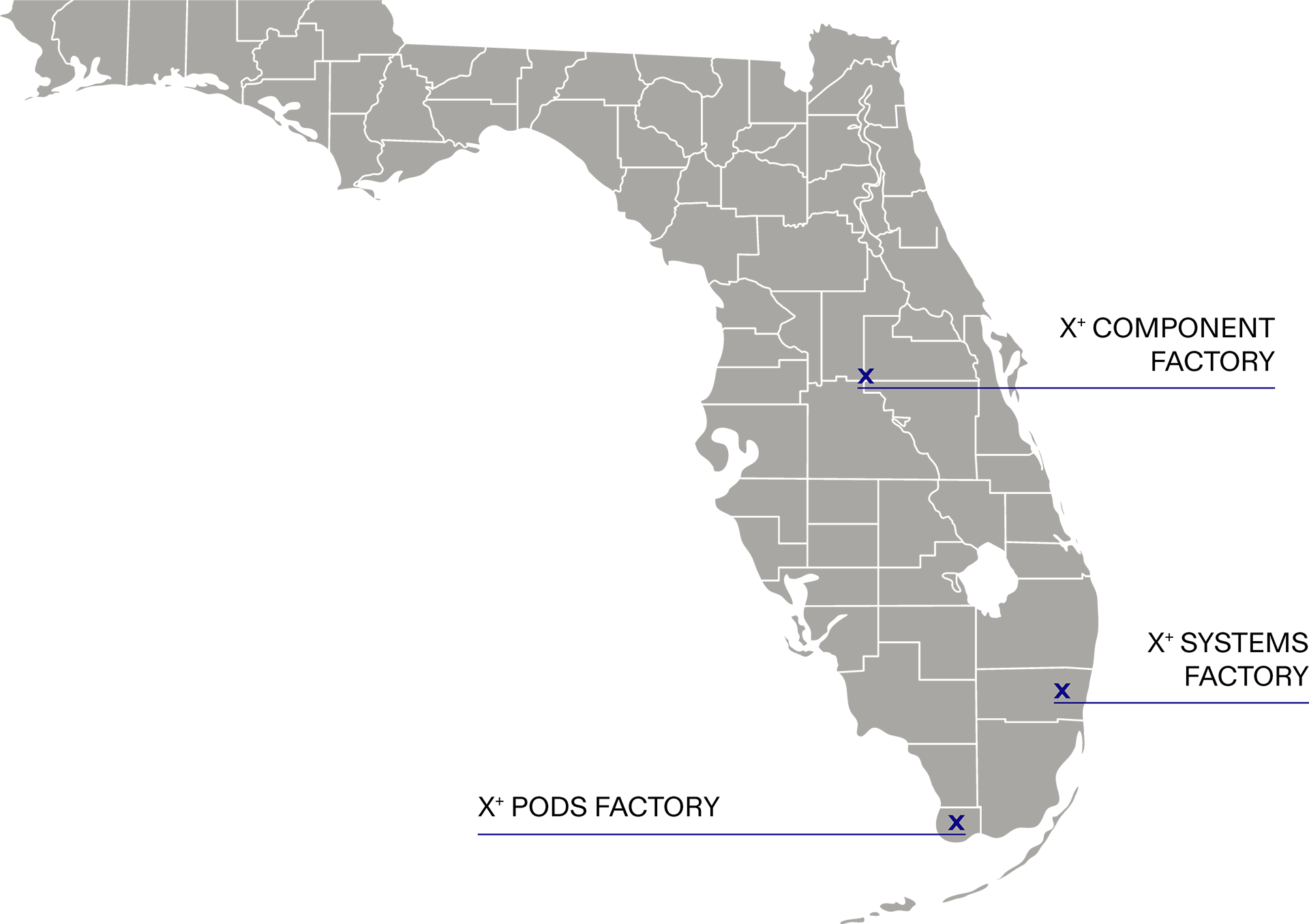

Where We Build

- South Florida

- Miami

- Fort Lauderdale

- Palm Beach

- Orlando

- Kissimmee

- Sanford

- Palm Bay

- Melbourne

- Titusville

- Lakeland

- Winter Haven

- Sarasota

- Bradenton

- Cape Coral

- Fort Myers

- Daytona Beach

- Ormond Beach

- Port St. Lucie

- Gainesville

- Naples

- Vero Beach

- Villages

- Punta Gorda