Onx Homes Officially Launched its 150,000-Square-foot Facility in Pompano Beach

Published on March 29, 2024

Onx Homes officially launched its 150,000-square-foot facility in Pompano Beach, where the startup manufactures prefabricated components for houses.

The $50 million homebuilding factory will support 70 jobs, including logistics roles and on-site assembly workers. Headquartered in Texas, Onx is constructing homes in six communities across Florida, including a site in Homestead. The Pompano factory will help the company scale production to build up to 700 homes a year.

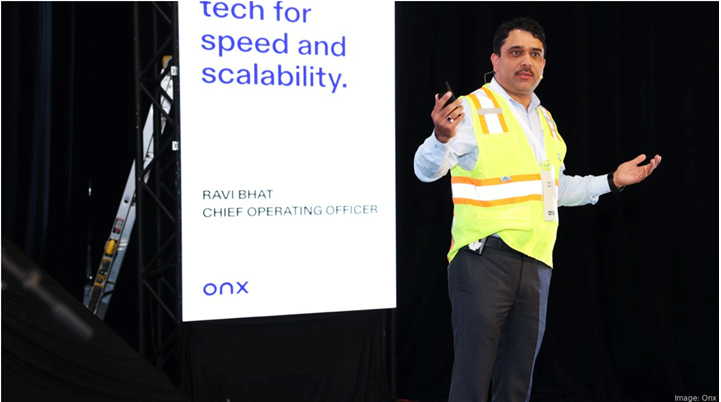

Pompano Beach’s proximity to seaports in Broward County makes it a prime location for the facility because much of Onx’s supply chain is shipped in from Mexico, South America and the Middle East, said COO Ravi Bhat. The facility’s location in South Florida makes it easy to access materials from the port.

“From a sustainability standpoint we want to be close to our supply chan,” Bhat told the Business Journal. “We’re very mindful of our carbon footprint.

The Pompano factory will manufacture the walls used to construct its homes, he added. Windows will be installed in the walls before they transferred to building sites.

Onx stands out from other homebuilders because it manufactures prefabricated parts for single-family houses and townhouses and then assembles them on-site. The company manages everything from the design to construction, a process that it says enables it to build a home from start to finish in less than 30 days.

“The only way to achieve that at that speed is to control every step,” Bhat said. “We have our own architects, we manufacture all of our components, and build the homes ourselves.”

The houses, which range from about 2,200 to 2,700-square-feet, are built to withstand Category 5 hurricane winds. That, combined with built-in hurricane impact windows, can help lower insurance costs for homeowners, Bhat said.

Sustainability influences almost every element of the home designed by Onx. Concrete, for example, is typically bonded with cement, which releases carbon emissions. Bhat said Onx uses concrete with 40% less cement in an effort to reduce the carbon impact. It is also experimenting with a concrete that has no cement for future construction.

The concrete structures are embedded with installation to retain heat or air conditioning to help conserve energy, as well. In addition, every Onx home has a charger for electric vehicles.

Bhat said Onx’s manufacturing process helps it build homes for about 25% less than the industry standard.

“We build fast with less people and get our supplies directly from the source, so our costs are lower,” he said.

He declined to specify how much an Onx home costs for customers, but said they are sold at market price.

Founded in 2021, Onx is backed by $120 million in investor capital, according to data from Crunchbase. So far the startup has delivered more than 500 homes to customers across Florida, its first market. Now, it plans to take its homebuilding model national and enter markets in Texas, California, Arizona and Nevada this year.

Bhat said starting out in Miami-Dade County, a market with one of the strictest building codes in the country, was a benefit because it forced Onx to build structures strong enough to withstand extreme weather events like hurricane force winds.

“We’re taking that same design to Orlando, to California, to Texas,” Bhat said. “We know the homes are strong enough for any location.”