Housing Innovators Double Down On Resiliency Solutions

By: Jennifer Castenson, Contributor

Published on March 4, 2025

Rebuilding efforts are well underway in parts of the country recently hit by wildfires and hurricanes. These rebuilding efforts have many challenges — from dwindling federal support funds to local remediation efforts.

While recovery is happening, the many challenges can slow it down to a crawl. Modular home building company, Liv-Connected, was awarded a contract for recovery housing in Lahaina after the fires devastated the area in August 2023.

The award from the Federal Emergency Management Agency took almost a year, and after being awarded, the company scrambled to start construction six weeks later.

Although FEMA is meant to offer residents a temporary shelter for 18 months after a disaster, the year that it took to get there is detrimental to the health and emotional well-being of the residents who are living in limbo, and risk living in limbo again when a solution that lasts only a year and a half is offered.

Liv-Connected worked on disrupting that cycle by designing a house to be used permanently, and that could be used on multiple occasions for a more sustainable and efficient solution.

that time period, the homes could be donated to the state of Hawaii or considered for other permanent uses. With the Liv-Connected homes, that will be a valid option.

When considering the residents’ need to get back in a home quickly, the county realized that offsite construction was the right choice because it would deliver homes faster. Liv-Connected started manufacturing in Buena Vista, Colorado, with Fading West.

“At full capacity of both manufacturers, we were making four houses per day,” co-founder Jordan Rogove said. “We had a goal of 109 homes, which took two months. Only 10% of the homes have been rebuilt in the year and a half since the fire. From factory to foundation was a three-week period. The costs were $230 to $250 per square foot.”

Resiliency Part By Part

Given the many challenges rebuilding after a major disaster, the housing industry needs to take a more proactive approach. Manufacturers are driving change and developing more resilient products to contribute to a stronger future of housing.

GigaCrete is a manufacturer that has several solutions for resiliency and sustainability, including the GigaPanel and GigaHouse steel framed building system that can go up in a day and is engineered to withstand hurricane force winds and CA seismic zone 4. Plus, it features fire resistant interior finishes, and non-combustible, waterproof exterior finishes.

The system doesn’t need skilled labor and goes up quickly, so it is ideal for emergency and disaster relief homes and shelters.

LP Building Solutions manufactures sheathing and has recently launched six products with added enhancements for resiliency.

TechShield blocks up to 97% of the sun’s radiant heat from entering into the attic, keeping an attic up to 30 degrees cooler so it is more resilient to extreme heat, and also lowers AC use.

Casey Smyth, LP’s senior corporate brand manager for OSB, said that NovaCore is another solution to protect against extreme heat by creating a layer of continuous insulation and breaking thermal bridging.

The company also is approaching climate risk proactively with sustainability best practices, such as using 99% of each tree it harvests, with 100% from naturally renewable forests. Plus, its SmartSide products produce 54% less greenhouse gas emissions than fiber cement.

Although the products have a slight price premium, many of the products don’t need house wraps, so the installation time is cut down, even reducing the number of subcontractors.

Another manufacturer, Living Building Systems, offers the Bio-Block, a fire-resistant, mold, and rotproof, material that is self healing and can lower the home’s operating and insurance costs. The product also can be designed for specific market requirements, including seismic and wind.

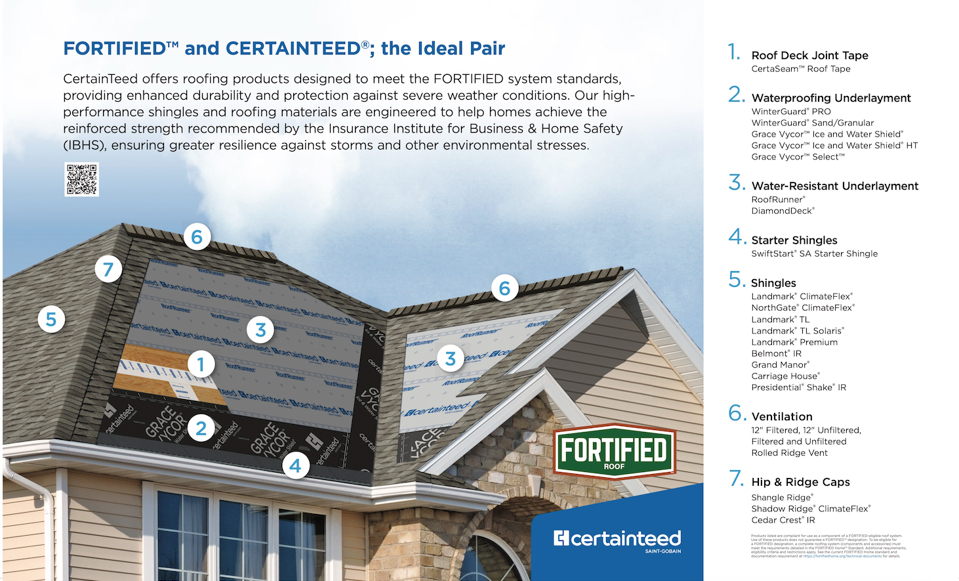

Building product company CertainTeed, secured FORTIFIED Roof certification for its roofing products, a program designed by the Insurance Institute for Business & Home Safety.

The program ensures that roofing solutions act as a system to strengthen roofs and protect homes — from the roof deck joint tapes to the underlayments, the shingles, and attic ventilation.

Paul Schmidt, CMO at Chemical Technologies Holding, shared the company’s innovative TechWood wood treatment that is warrantied against mold, rot, decay, termites, and fire. It is applied through a pressure less process so it is 100% eco-friendly and nonhazardous.

Its patented process creates a semipermeable protective barrier to slow the moisture movement outward, minimizing warpage, and protecting it from mold, rot and decay.

The Whole Resiliency Package

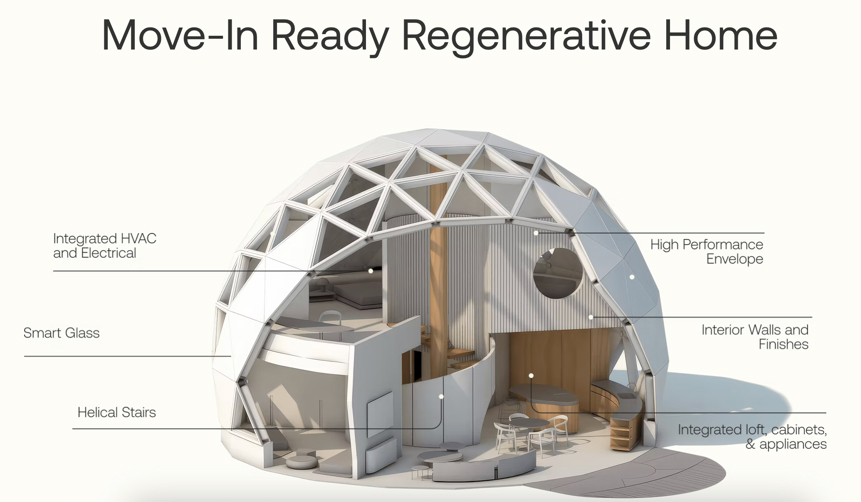

Geoship is a home that the company’s head of business development, Jean-Marc La Flamme, claims can cut the carbon footprint by 85% and reduce cost by 50%, and is resilient to fire, hurricanes and earthquakes.

It is constructed with a bioceramic, durable material made from raw minerals and natural fibers and that can withstand category 5 hurricane winds up to 250 mph.

While not a traditional home, it’s affordable and safe. The company’s first product, Amma, offers 1,530 square feet of living area and sells for $169,000, or $110 per square foot.

Ash Bhardwaj, CEO at offsite construction company Onx Homes, builds with concrete technology that can withstand 175 mph winds. Centered in the eye of hurricane risk, Florida-based Onx has built 700 homes in Florida and 25 in Texas, with 2,500 more under development in Florida and 1,500 in Texas.

“Our concrete foundation is 4 feet higher than the ground and higher than jurisdictions require,” Bhardwaj said. “Plus, with the concrete structure, by nature it is a hinderance to the fire, where wood is a catalyst to the fire.”

The company is investing in research and development to improve its capabilities for sustainable and resilient construction. For example, its next generation roofing system is designed to withstand a hail storm. These investments have a big pay off for homeowners.

He believes that resilient homes shouldn’t cost more and is focused on scaling his business while taking out all the inefficiencies in conventional home building to hit a low price point. Onx homes sell at $350,000 and up.

With housing in high demand, particularly after a storm, Onx’s offsite process is faster than traditional construction. Onx factories can produce 1,500 homes per year in Florida and 400 in Texas. A new Orlando factory is planned for 2026. Onx invested $50 million in 2024 and plans to invest $75 million in 2025 to support expansion and technological advancements, such as a new factory in 2026, and 8 new Florida developments in 2025.

A recent report from First Street, a financial risk data company, shows a forecast of major real estate disruptions in these states. Historical population migration to the Sun Belt, which has dominated U.S. population movement for decades, is being fundamentally disrupted by climate change impacts.

The three largest Sun Belt states (Texas, Florida, and California) have absorbed more than 40% of the $2.8 trillion in natural disaster costs since 1980.

MDLR Brands also is manufacturing modular homes that hold up to Category 5 hurricanes with wind testing up to 155 mph. The homes are fire resistant with a 30-minute to 1-hour fire rating and self extinguishing properties

Airbnb.org is providing emergency shelter for residents after natural disasters. After the recent Los Angeles wildfires, in partnership with 211 LA, the organization provided emergency housing to more than 17,000 people who lost their homes or were forced to evacuate.

Christoph Gorder, Airbnb.org’s executive director, said that the company’s technology enables it to provide a critical source of flexible, emergency housing for cities, particularly during natural disasters.

Not only are there holistic physical solutions, but Melissa Sterry is the founder and director of the Panarchic Codex, a practice to design for living with wildfire. She is launching a Design for Wildfire school to share her leadership in designing for wildfire resilience using adaptive architectural and urban systems that mimic, synthesize, and synchronize with the local ecosystem.

The Future

These innovative solutions are in high demand and investors are seeking ways to fund them. Accelerators also are popping up to catalyze new ideas.

The Conversation XLabs is hosting an open innovation competition with more than $1,000,000 in prizes to support innovation in scalable solutions to live and thrive with fire. This year judges will select 12 finalist teams to receive $50,000 for field testing these solutions in a 9-month accelerator program.

I will be part of a session at the PropTech House @SXSW event on Sunday, March 9 on climate resistant housing strategies, along with a panel session at the 2025 SXSW Conference, Building and Protecting Homes in a Changing Climate: Challenges and Strategies, scheduled Tuesday, March 11. During these sessions, we’ll explore the challenges and the opportunities for the housing market to adapt to climate threats.

It’s time for all housing stakeholders to step up to the demands for more resiliency. Working together, we can create safer places to live that can combat future climate risks.